How to Measure Louver Airflow Performance

Why Measuring Airflow Performance is Critical

In architectural and mechanical design, louver airflow performance directly affects ventilation efficiency, cooling capacity, and energy consumption. Unlike visual specifications such as free area percentage, performance must be measured using scientific methods that reflect real operating conditions. Selecting louvers without considering airflow performance risks higher fan power, lower system efficiency, and unexpected operational failures.

Key Performance Indicators

1. Discharge Loss Coefficient (DLC)

The Discharge Loss Coefficient measures how effectively a louver passes airflow. A lower DLC value means better airflow efficiency, less resistance, and reduced energy consumption. High-quality air performance louvers are engineered to minimize losses while maintaining weather protection.

2. Pressure Drop

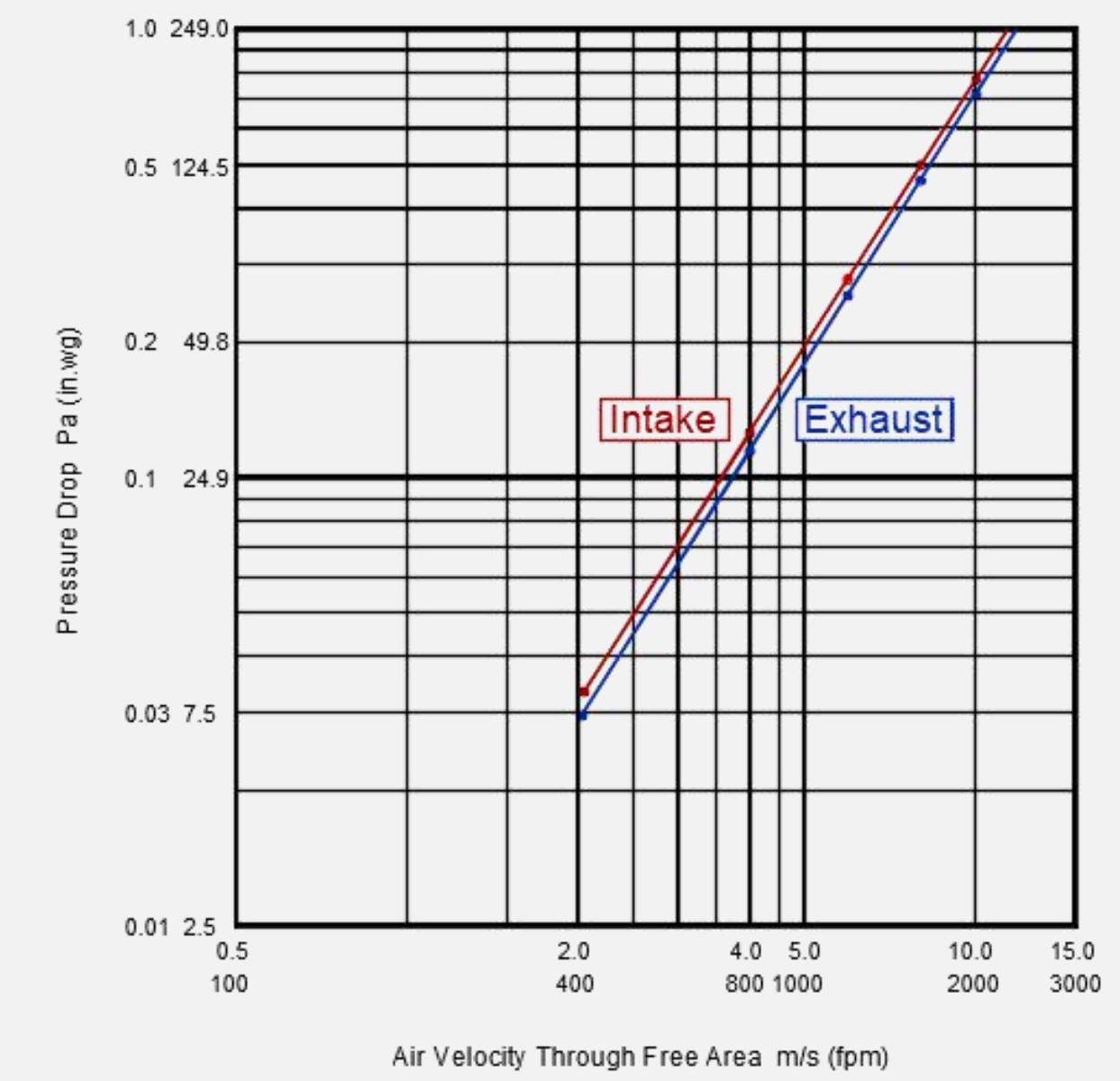

Pressure Drop represents the resistance created by the louver when air passes through. For a given air volume, higher pressure drop means the fan must work harder, consuming more energy. Weather louvers perform differently at different face velocities, making it critical to test louvers under conditions that reflect the project’s actual operating airflow.

The Limitations of Free Area

Although Free Area (%) is widely promoted in the market, it is not a reliable indicator of louver performance. Free area only considers geometric openings, ignoring aerodynamic effects and airflow resistance. Relying solely on free area can mislead design decisions.

The limitations of Free Area:

· ❌ Does not reflect airflow characteristics – Two louvers with the same free area may have very different airflow resistance due to blade geometry.

· ❌ Ignores velocity and pressure drop relationship – Free area only measures open space, without accounting for real operating pressure losses.

· ❌ Leads to poor product selection – Choosing louvers based only on free area may result in high pressure drop and insufficient airflow, reducing system efficiency.

· ❌ Not aligned with international standards – Leading standards such as EN 13030, AMCA 500-L, and AS 4740 do not use free area as the sole performance criterion.

This is why performance testing — not free area — must guide louver selection.

International Testing Standards

Global standards define how performance louvers should be evaluated:

· EN 13030 – Performance testing for weather louvers.

· AMCA 500-L – Air performance and water penetration testing.

· AS 4740 – Australian standard for louver airflow and weather performance.

These standards emphasize measurable performance (DLC, pressure drop, airflow capacity) rather than free area alone.

Test, Don’t Guess

Measuring louver airflow performance with Discharge Loss Coefficient and Pressure Drop ensures reliable selection, energy efficiency, and long-term durability. Free area may provide a quick visual reference, but it cannot replace certified performance testing.

At Vanman, we provide AMCA-tested performance louvers and weatherproof louvers engineered to meet international standards, ensuring your building achieves both safety and efficiency. Contact us today for professional louver solutions.